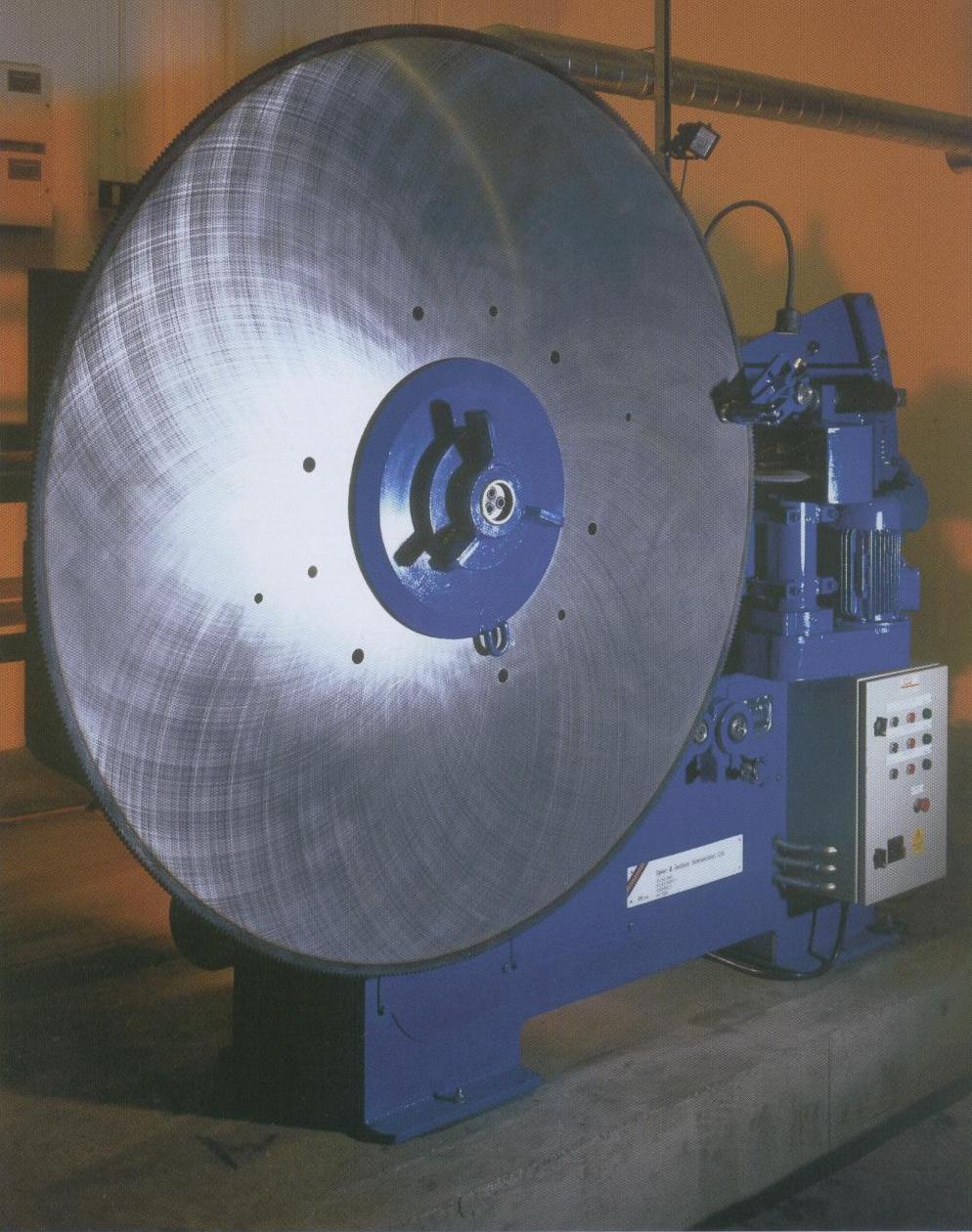

POWERGRINDER

What is it?

The POWERGRINDER has been designed for the sharpening of hot and friction saw blades in steel mill and blade repair facilities. This revolutionary sharpening machine, under patent application, has been specifically designed for sharpening blades from 1400mm diameter up to 2400mm (55 inches – 94 inches).

The strength and durability of the machine, particularly the grinding head, enables the easy repair of large diameter blades.

The machine offers unique efficiency and speed in the reforming of the tooth profile, on blades from 6mm to 16mm thick (1/4 – 5/8 inches).

Individual design features such as sealed for life bearings ensure minimum maintenance of the machine is required.

Key Features:

Machine strength and durability

Minimum maintenance

Easy installation – no specialised foundations required

Reduced regrinding time – up to 30% faster than other grinding machines

Operator friendly – easy access to operator controls and grinding head

Contact us to find out more about how the POWERGRINDER and POWERFLAME work in conjunction. We can talk you through their roles and how they can help your business.

Machine Specification:

Variable Grinding Stroke from 10mm – 50mm (3/8 – 2 inches)

35 Strokes per minute

Heavy duty precision ground shafts for grinding head oscillation

Electrical specification supplied compatible to customer requirements

Up to 20 Degree tilt on grinding head for different tooth forms

Gravity fed forward stroke via internal counterweight system to prevent excessive load on grinding head

Individual stop / start and operation lights for: Grinding wheel motor, oscillation motor and dust extraction motor

Side floating arbor mounting for accurate blade centring

Reinforced bellows to protect slide ways from grinding dust

Automated cleaning system on Extraction Unit

Hollow shaft ventilation system for effective dust extraction

Flexible light on grinding head for easy observation of grinding process